Our Pellets

In Continuous Improvement

Our Product

Our product is the subject of constant research and a permanent requirement, thus becoming the first manufacturer to obtain the ENplus A1 Certification in Germany and today achieving all the certifications of both quality and sustainability that are possible.

We only offer the best quality pellets to our customers, using the best raw materials and having a constant and rigorous control of our manufacturing process.

Our Pellets are certified in the EN PLUS A1 and DIN PLUS quality standards and from the environmental point of view they have the PEFC and FSC certification.

In addition, our analytics greatly improve the requirements of quality standards, which results in a product with higher quality and less waste, being more efficient and reducing consumption.

Environmental commitment is one of the challenges of our company. Stand Pellets strive to be part of the solution to global challenges such as climate change.

Arde Pellet has 3 main sales references: the 15kg bagged pellet, the bulk pellet, and the bulk format.

Our 100% recycled and recyclable plastic bags are ENplus A1 and PEFC certified.

We have opted for the use of recycled plastics, carrying out an ECODESIGN for the elaboration of our 15kg bags.

What is the pellet?

Pellets are small cylinders of wood made by pressing previously dried, screened, and refined wood by-products. The raw material is natural wood, without any type of additive or treatment, from the by-product of the industry of the 1st transformation of wood (sawdust, chips, and debarked firewood).

Pellets have a high calorific value and are clean and easy to handle. Its combustion is neutral in CO2 emissions. The ash content of the pellet is very low, less than 0.5%, and, as it comes exclusively from natural wood, the ashes it produces can even be used as valuable fertilizer.

Wood is a natural and renewable resource, which is why it is the ideal and safe solution for a long-term supply of fuel for heating. During their growth process, trees absorb CO2 from the air, which is later released during combustion in exactly the same proportion. In this way, CO2 emissions during combustion are not higher than those that would be produced during the natural decomposition of trees in the forest. In this way, the sensitive balance cycle of CO2 in the atmosphere is not altered.

It is also a very profitable fuel from an economic point of view. More stable in terms of prices than traditional fossil fuels, it represents savings of between 20 and 40% compared to these fuels.

What are the advantages of the pellet?

- It is a natural, locally sourced, and renewable product

- CO2-neutral emissions

- Easy and clean transport, distribution, and storage

- They offer great heating comfort

- Stable in times of crisis

- It supposes an important economic saving compared to fossil fuels or electrical energy.

How do we make it?

The raw material is natural wood from the by-product of the industry of the 1st transformation of wood (sawdust, chips, and debarked firewood).

It is then subjected to a screening, crushing, and refining process before proceeding to its drying.

The drying process is carried out using a band dryer that works at low temperatures, respecting the nature of the wood as much as possible and avoiding contamination with ashes. After drying, new screening and refining are carried out. Finally, they are pressed, giving them their characteristic density, durability, and cylindrical shape.

In the pressing process, no additives are used, the wood’s own lignin is the one that acts as a binder and gives it its shiny exterior appearance.

Subsequently, bagging is carried out, prior to which two screening processes are carried out, thus guaranteeing a clean final product free of fines.

The final result is a product of the highest quality, which does not fall apart, without fines, with a very low percentage of ash and high calorific value.

How is our pellet different?

Our product is the subject of constant research and a permanent requirement, thus becoming the first manufacturer to obtain the ENplus A1 Certification in Spain and today achieving all the quality and sustainability certifications that are possible.

Our analytics show that the product we manufacture far exceeds the standards established by these quality standards, as can be seen below:

Our Packaging

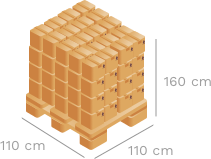

The packing that most identifies Arde pellet is, without a doubt, its 15 kg bag. The presentation of the pallets is always 72 bags, therefore the full load is 22 pallets per truck.

References

Weight

Units

72 bags